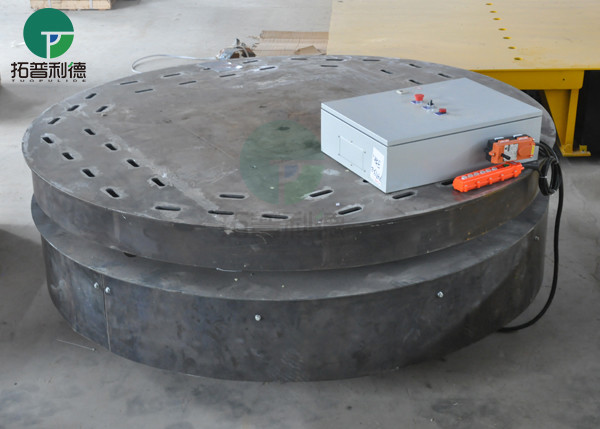

Factory stable heavy load rail electrical turntable transfer cart

Product Introduction --- Pallet Motorized Railway Turntable

Factory stable heavy load rail electrical turntable transfer cart is a kind of equipment to realize the spot turning and reversing of the track flat car. It is installed at the crossing position of two tracks, and one or more tracks are laid on the platform. The upper surface of the track is flush with the upper surface of the track on the ground, and the track gauge is consistent with that on the ground. The flat car starts again and runs along the track after docking to the required position, so that it can stop at any Angle of 360 degrees, and can also realize the well type cross operation. It is suitable for annular track, cross track and other occasions equipped with the production line. The turntable system runs smoothly, the track docking accuracy is accurate, and the automatic electrical control can also be realized. The turntable is arranged in a circular pit, and the surface of the turntable is flush with the ground.

Technical Parameter --- Pallet Motorized Railway Turntable

| Model |

BZP-30T Turntable |

| Rated Load(t) |

30 |

| Table Dia(mm) |

2500 |

| Rail Gauge(mm) |

1435 |

| Power supply |

3P 380v |

| Rotating speed(r/p) |

1 |

| Turning degree |

0-360 |

| Motor power |

3 |

| Recommended Rail Model |

P24 |

| The parameter is just for reference, all of the our turntables are customized according real applications |

Applications --- Pallet Motorized Railway Turntable

The pallet motorized railway truntable is mainly applied in assembly line (ring production line, loop production line), metallurgy industry (steel ladle), warehouse transport, ship industry (maintenance, assemble, container transport), workpiece transport in workshop, lathe transport.

Package & Delivery --- Pallet Motorized Railway Turntable

Company Brief

Requirements for Pallet Motorized Railway Turntable

1. Control System

There is a control box on the ground, and the control box is equipped with left-handed, right-handed, click-and-stop buttons and corresponding indicator lights.

2. Rust Removal And Painting Requirements

The surface rust removal of steel plate, profile and forging reaches ST2 grade in GB8923. The film thickness is 90-120 um. Rust-proof treatment is carried out on all exposed surfaces before leaving the factory. The surface is coated with rust-proof primer, dark gray topcoat, and the guide rail is not painted.

3. Control Box System

The control box is made of steel plate. It is beautiful and practical. The surface is anticorrosive. The thickness of the box body is not less than 2 mm. It has a good heat dissipation device. There is a practical overhaul lamp in the control box. The door lock is firm and reliable. It is easy to use and does not interfere.

4. Equipment Configuration

All kinds of famous industrial components should be selected to ensure the overall reliability of the equipment.

5. Frame System

The frame frame structure consists of longitudinal beam, cross beam and steel plate. The working table is paved with steel plate. The profiles and steel plates used conform to the corresponding national standards.

6. Transmission System

The motor drives the reducer, transfers the power to the rotary device, and drives the rotary table to rotate. The components are reliably connected with the main body. The motor adopts brake motor, the protection level is IP44.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!