How to Use Heat Shrink Wire Connectors for Secure and Durable Connections

In the world of electrical connections, ensuring secure and durable outcomes is paramount. Experts in the field often emphasize the importance of using the right materials, particularly when it comes to heat shrink wire connectors. John Smith, a recognized authority in electrical engineering, asserts, “Using heat shrink wire connectors enhances the longevity and reliability of electrical connections, making them essential for both professionals and DIY enthusiasts.”

Heat shrink wire connectors are designed to provide a robust seal against moisture, debris, and other environmental factors, which can compromise electrical integrity. As electrical applications become increasingly sophisticated, the demand for safe and durable connections has never been higher. By utilizing heat shrink wire connectors, users can create connections that withstand the test of time and various conditions, ultimately improving the performance of their electrical systems.

This guide will delve into the effective use of heat shrink wire connectors, highlighting techniques, best practices, and tips to ensure successful application. From choosing the right size to mastering the installation process, understanding these components is crucial for achieving optimal results. With the insights provided, both novices and seasoned professionals can enhance their skills and confidence in creating lasting electrical connections.

What Are Heat Shrink Wire Connectors and Their Benefits?

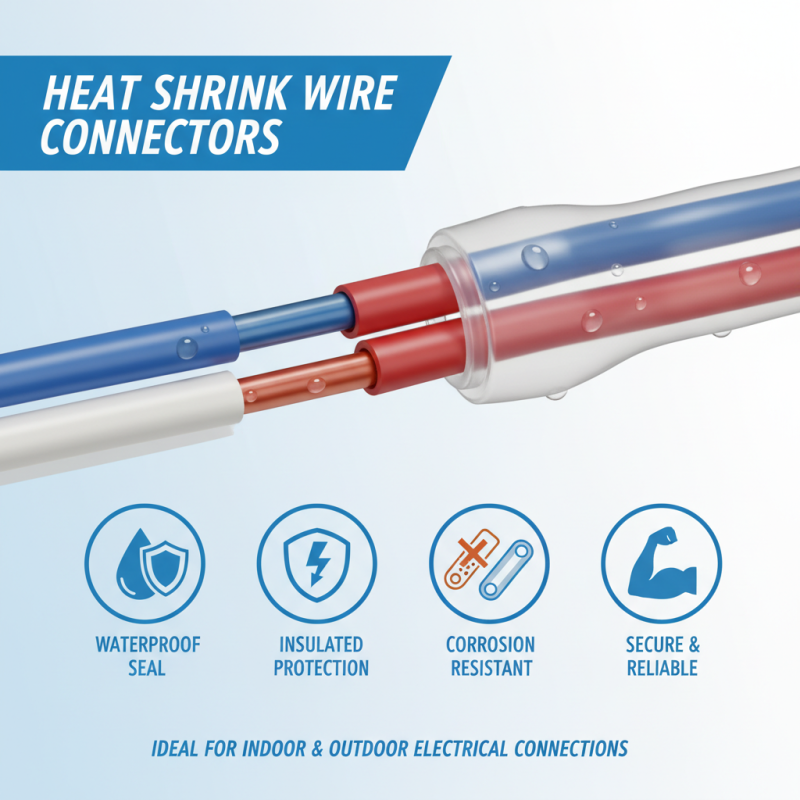

Heat shrink wire connectors are specialized electrical connectors designed to provide secure and reliable connections for wires and cables. These connectors consist of a metal crimp and a heat shrinkable plastic housing, which shrinks tightly around the connection when heat is applied. This process creates a waterproof and insulated seal that protects the joint from environmental factors such as moisture, dust, and corrosion, making them ideal for both indoor and outdoor applications.

One of the primary benefits of heat shrink wire connectors is their durability. The heat shrink material not only ensures a tight fit around the connector but also reinforces the connection, reducing the risk of accidental disconnection over time. Additionally, these connectors offer superior resistance to heat and cold, which is particularly important in automotive or industrial settings where temperature fluctuations can occur. By using heat shrink wire connectors, users can achieve a robust and long-lasting connection that enhances the overall integrity of their electrical systems.

Essential Tools Needed for Working with Heat Shrink Wire Connectors

When working with heat shrink wire connectors, having the right tools is essential for achieving secure and durable connections. The fundamental tools required include a heat gun or lighter, wire strippers, crimping tools, and electrical tape. The heat gun is particularly important, as it evenly distributes heat to shrink the connector, ensuring a tight fit around the wire. According to a report from the National Electrical Manufacturers Association (NEMA), improper heat application can reduce the effectiveness of wire connections, leading to potential issues in both safety and functionality.

In addition to the basic tools, investing in quality wire strippers and crimping tools can greatly enhance the quality of your connections. A study by the Institute of Electrical and Electronics Engineers (IEEE) emphasized that poorly stripped wires or inadequate crimping can result in increased resistance at the connection point, which may lead to overheating or failure. Using precise wire strippers to remove the insulation without nicking the wire strands, along with a reliable crimping tool to secure the connectors, will promote optimal performance and longevity of electrical systems.

Lastly, having electrical tape on hand is crucial for additional insulation and protection against moisture and environmental factors. The Electrical Safety Foundation International (ESFI) notes that environmental exposure is a leading cause of wire connection failure. Properly sealing connections with electrical tape can mitigate these risks, contributing to the overall safety and reliability of electrical installations. With the right tools and techniques, users can ensure that their heat shrink wire connections remain robust and dependable over time.

Step-by-Step Process for Preparing Wires for Connection

Preparing wires for connection using heat shrink wire connectors is a straightforward process that ensures secure and durable electrical connections. The first step involves stripping the ends of the wires. For an effective connection, about half an inch of insulation should be removed from each wire using wire strippers. This exposes the copper strands, which will later be twisted or inserted into the connector. It’s essential to avoid damaging the wire strands, as this could lead to poor connectivity.

Once the wires are stripped, the next step is to insert them into the heat shrink connector. Ensure that the exposed copper from each wire fits snugly inside its respective barrel of the connector. For twisted connections, carefully twist the wire strands together to create a solid bond before insertion. After the wires are in place, use a heat gun to apply heat evenly along the length of the connector. This will cause the shrink tubing to contract tightly around the wires, creating a waterproof seal and excellent electrical insulation, ensuring the connection remains robust over time.

Techniques for Properly Installing Heat Shrink Wire Connectors

When installing heat shrink wire connectors, proper technique is essential for ensuring secure and durable connections. According to a report by the International Wire and Cable Manufacturer’s Association (IWCMC), approximately 15% of all electrical failures in industrial applications arise from inadequate wire connections. To mitigate these risks, it's critical to select the appropriate heat shrink tubing that matches the wire gauge and environmental conditions. A good practice is to use connectors with an inner adhesive that not only provides a waterproof seal but also reinforces the mechanical strength of the connection.

Before applying heat, it’s important to prepare the wires properly. Stripping the insulation should be done with precision—removing just enough material to make a solid connection without compromising the wire itself. Industry standards recommend a strip length of approximately 1/4 inch for most applications. After inserting the wire into the connector, a uniform heat application is vital. The use of a heat gun is preferred over an open flame, as it allows for controlled heating, thus ensuring the tubing shrinks evenly and the adhesive flows adequately. Maintaining a distance of approximately 6 inches from the heat source can help avoid overheating and damage to the wire itself, which can prolong the life of the installation substantially.

Lastly, it's beneficial to allow the connection to cool naturally after heating, as this ensures the adhesive forms a strong bond with the wire and connector. Studies show that properly installed heat shrink connectors can reduce the failure rate of electrical systems by up to 30%, providing both reliability and peace of mind in various applications.

Tips for Ensuring Long-Lasting and Reliable Electrical Connections

When using heat shrink wire connectors, ensuring long-lasting and reliable electrical connections requires attention to several key factors. First, selecting the right size and type of connector is crucial. According to a report by the International Electrotechnical Commission, approximately 25% of electrical failures in industrial applications are attributed to improper connections, emphasizing the need for correct sizing. Connectors should match the gauge of the wires being joined to avoid overheating and ensure a snug fit, which facilitates a better seal when heat shrink is applied.

Additionally, proper preparation of the wire ends is essential. The National Electrical Manufacturers Association (NEMA) suggests stripping wires to the correct length and twisting or crimping them securely before applying the heat shrink tube. This helps prevent moisture ingress and reduces the risk of connection failure. Furthermore, applying heat evenly during the shrinking process is vital, as uneven heating can lead to weak spots in the connection. Studies indicate that using a heat gun, rather than an open flame, ensures a more uniform application of heat, thus enhancing the mechanical strength of the connection and the integrity of the electrical flow. By following these practices, users can significantly enhance the longevity and reliability of their heat shrink wire connections.

Heat Shrink Wire Connectors Usage Statistics

Related Posts

-

Top Quality Electrical Wire Connectors From a Leading Chinese Manufacturer for Global Export

-

Understanding Wire Nuts: Essential Tips for Safe Electrical Connections

-

7 Benefits of Using Flat Plug Extension Cords for Home and Office Efficiency

-

The Ultimate Guide to Choosing the Right Outdoor Extension Cord for Your Needs

-

Top 10 Types of Electrical Cables You Need to Know for Your Projects

-

How to Maximize Your Gains with a Smith Machine with Cables for Effective Resistance Training