Top Quality Electrical Wire Connectors From a Leading Chinese Manufacturer for Global Export

In the ever-evolving electrical industry, the significance of top-quality electrical wire connectors cannot be overstated. As the global market for electrical connectors is projected to reach USD 80 billion by 2027, driven by advancements in technology and increasing demand across various sectors, manufacturers are under pressure to meet high standards of reliability and performance. In particular, the need for robust electrical wire connectors is growing, as they play a crucial role in ensuring safe and efficient electrical connections in everything from residential buildings to industrial applications. Industry reports indicate that improper connections can lead to severe safety hazards, including electrical fires, which not only endanger lives but also incur significant economic losses. As a leading Chinese manufacturer, we are committed to delivering top-quality electrical wire connectors that address these crucial challenges and comply with international safety standards, thus supporting global export needs.

Understanding the Importance of High-Quality Electrical Wire Connectors

High-quality electrical wire connectors are crucial components in any electrical system, ensuring safe and reliable connections. Poor-quality connectors can lead to a multitude of problems, including overheating, electrical failures, and even fire hazards. In industries where safety and efficiency are paramount, using top-grade connectors becomes indispensable. These connectors guarantee optimal conductivity and longevity, reducing the likelihood of maintenance issues and downtime.

Furthermore, the reliability of electrical wire connectors significantly impacts overall system performance. A well-designed connector can withstand various environmental conditions, such as temperature fluctuations and humidity, ensuring consistent operation under demanding circumstances. As global demand for dependable electrical solutions continues to rise, sourcing high-quality connectors from leading manufacturers, such as those in China, can provide businesses with the assurance they need. This enables them to focus on their core operations while maintaining high safety standards in their electrical installations.

Top Quality Electrical Wire Connectors From a Leading Chinese Manufacturer for Global Export - Understanding the Importance of High-Quality Electrical Wire Connectors

| Connector Type | Material | Current Rating (A) | Voltage Rating (V) | Temperature Rating (°C) | Application |

|---|---|---|---|---|---|

| Butt Connector | Copper | 15 | 600 | 85 | Automotive Wiring |

| Ring Terminal | Brass | 25 | 480 | 105 | Industrial Equipment |

| Splice Connector | Aluminum | 30 | 1000 | 70 | Power Distribution |

| Quick Disconnect | Stainless Steel | 10 | 300 | 90 | Home Appliances |

| Wire Connector Block | Nylon | 20 | 600 | 75 | Lighting Systems |

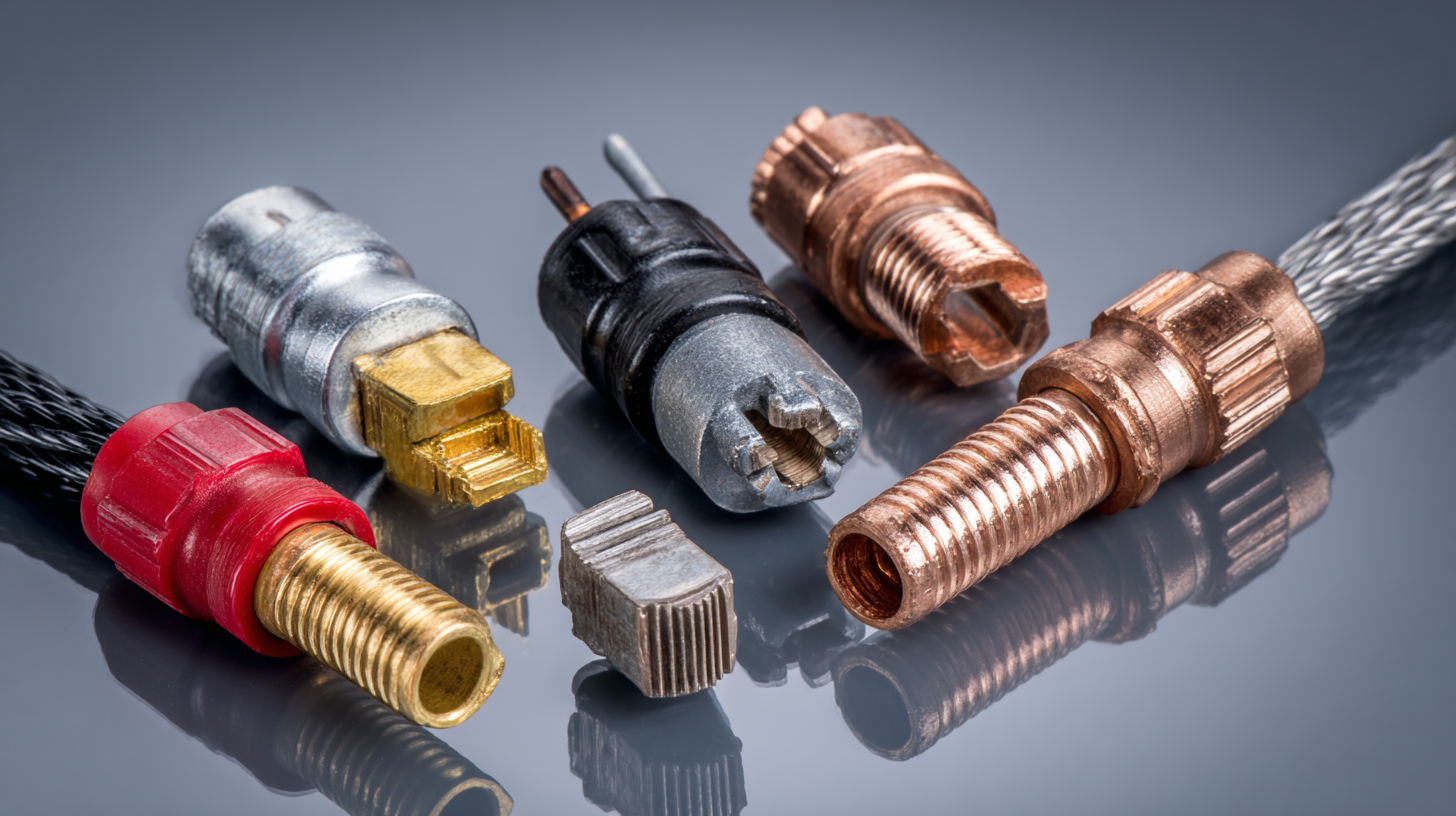

Key Features to Look for in Electrical Wire Connectors

When choosing electrical wire connectors, it's essential to prioritize quality and compatibility. First and foremost, look for connectors that are made from durable materials such as high-grade thermoplastics and metals that can withstand various environmental conditions. Quality connectors should also feature corrosion-resistant finishes to prolong their lifespan, especially in outdoor or humid settings.

Another critical aspect is the electrical rating of the connectors. Ensure the connectors you select can handle the required voltage and current levels for your specific application. Additionally, consider the design of the connectors; for instance, connectors with secure locking mechanisms can prevent accidental disconnections, which is vital for safety and reliability.

Tips for selecting the right electrical wire connectors include checking for certifications from recognized standards organizations. This not only guarantees quality but also ensures that the connectors meet international safety regulations. Also, it's beneficial to choose connectors that offer easy installation features, such as clear labeling and user-friendly designs, to save time and reduce installation errors.

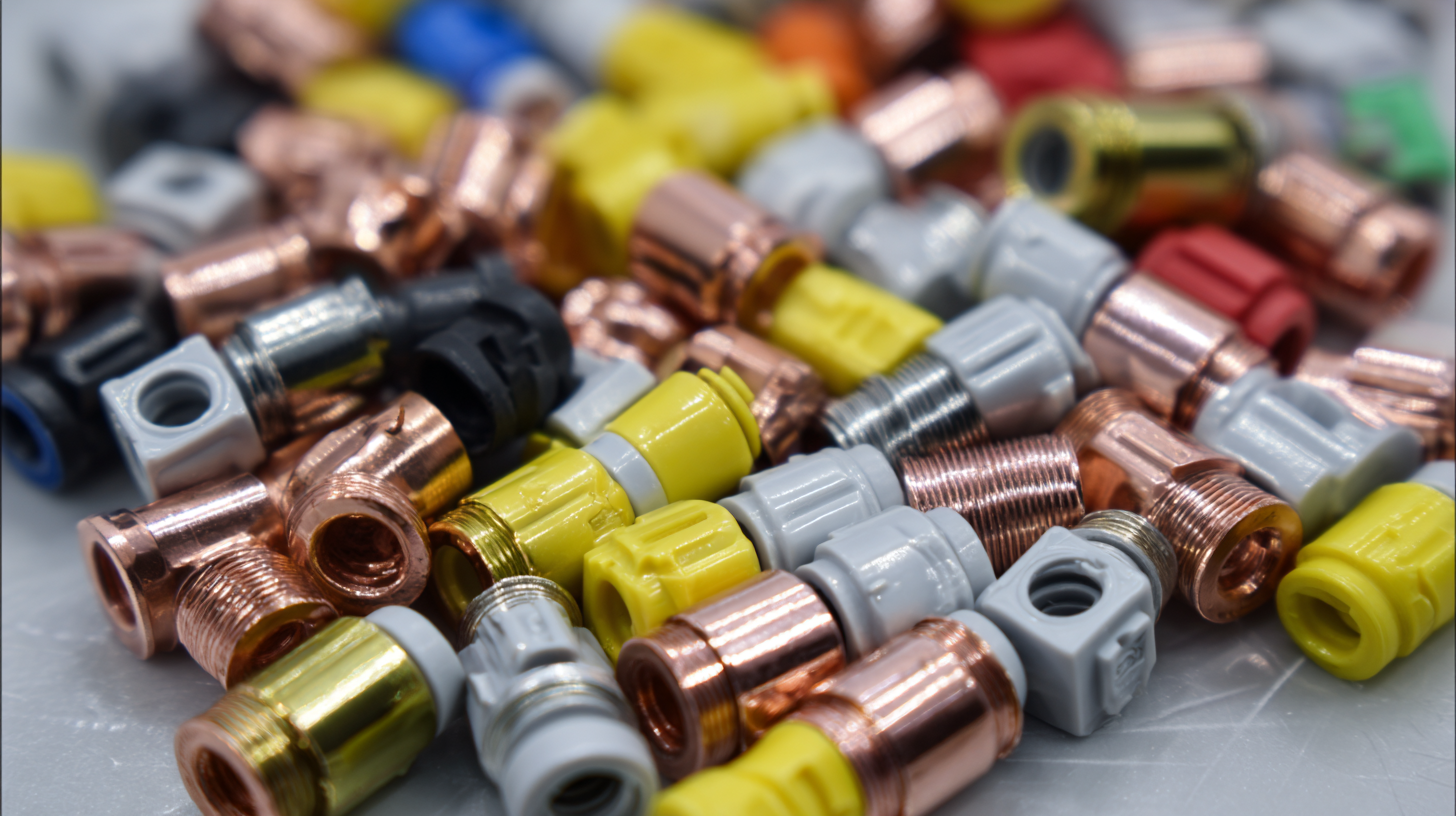

Benefits of Choosing a Leading Chinese Manufacturer for Global Export

When considering electrical wire connectors for global export, selecting a leading Chinese manufacturer can offer numerous advantages. As China's innovation capabilities continue to grow, driven by advancements in technology and manufacturing processes, businesses can benefit from high-quality products that meet international standards. With a focus on producing reliable electrical components, these manufacturers are well-positioned to cater to the varying needs of global markets.

Tip 1: Research the manufacturer’s quality certifications and standards compliance to ensure their products meet the required safety and performance benchmarks applicable in your region.

The current global trade dynamics present a unique opportunity for companies to partner with Chinese manufacturers. As the U.S. pulls back from certain trade agreements, China is stepping up its role in global supply chains, making it easier for businesses to source top-quality materials with competitive pricing.

Tip 2: Evaluate the manufacturer’s track record and customer reviews to gauge their reputation and reliability in exporting goods, ensuring you choose a partner that can deliver consistently.

By selecting a leading Chinese electrical connector manufacturer, businesses can capitalize on the country's rapid innovations while enjoying the benefits of cost-effectiveness and quality assurance.

Installation Tips for Optimal Performance of Electrical Wire Connectors

When it comes to ensuring optimal performance of electrical wire connectors, proper installation is crucial. According to the International Electrotechnical Commission (IEC), improper wiring can lead to a 30% increase in failure rates, significantly impacting system efficiency and safety. To mitigate these risks, adhere to the following essential tips.

First, always choose connectors that are compatible with the wire gauge being used. A mismatch can result in poor electrical conductivity and potential overheating. The National Electrical Manufacturers Association (NEMA) recommends that the connector's current rating should exceed the actual current that will flow through the circuit by at least 25%. This ensures a safety margin that can accommodate unexpected surges and extends the lifespan of the connectors.

Another critical aspect is to maintain a clean working environment. Dust and moisture can adversely affect the integrity of electrical connections. According to a study by the Institute of Electrical and Electronics Engineers (IEEE), contaminants can lead to corrosion, ultimately resulting in a 20% reduction in connector performance. Always clean the surfaces before installation and use appropriate sealing solutions to protect connectors from environmental factors, ensuring long-lasting, reliable performance.

Quality Assurance Standards in Electrical Wire Connector Manufacturing

Quality assurance is pivotal in the manufacturing of electrical wire connectors, as these components are crucial for ensuring electrical safety and efficiency. Leading Chinese manufacturers adopt stringent quality assurance standards that align with international norms. This includes rigorous testing of materials, precision in manufacturing processes, and adherence to certifications such as ISO and IEC. By implementing these standards, manufacturers can ensure that their products deliver reliable performance in various applications, from residential wiring to complex industrial setups.

In addition to adhering to established standards, manufacturers often incorporate advanced technology and engineering practices to enhance the durability and effectiveness of their connectors. Regular audits and inspections throughout the production process help identify potential defects early, allowing for swift corrective actions. The commitment to continuous improvement and innovation not only elevates the quality of electrical wire connectors but also builds trust with global clients who seek dependable products for their specific needs. With such meticulous quality assurance practices in place, manufacturers are well-positioned to compete in the global marketplace, offering top-quality connectors that meet diverse industry demands.