How to Choose the Best Waterproof Wire Connectors for Your Projects

Choosing the right waterproof wire connectors for your projects is crucial for ensuring safety, durability, and optimal performance in various environments. With the global market for waterproof connectors projected to reach $4.54 billion by 2025, driven by increasing demand in industries such as automotive, aerospace, and marine, understanding the best options available is more important than ever. According to a recent industry report, nearly 60% of failures in electrical systems can be traced back to improper connections, highlighting the necessity of selecting high-quality waterproof wire connectors that can withstand moisture, dirt, and environmental stressors. In this guide, we will explore the essential factors to consider when evaluating waterproof wire connectors to help you make informed decisions that enhance the reliability and longevity of your projects.

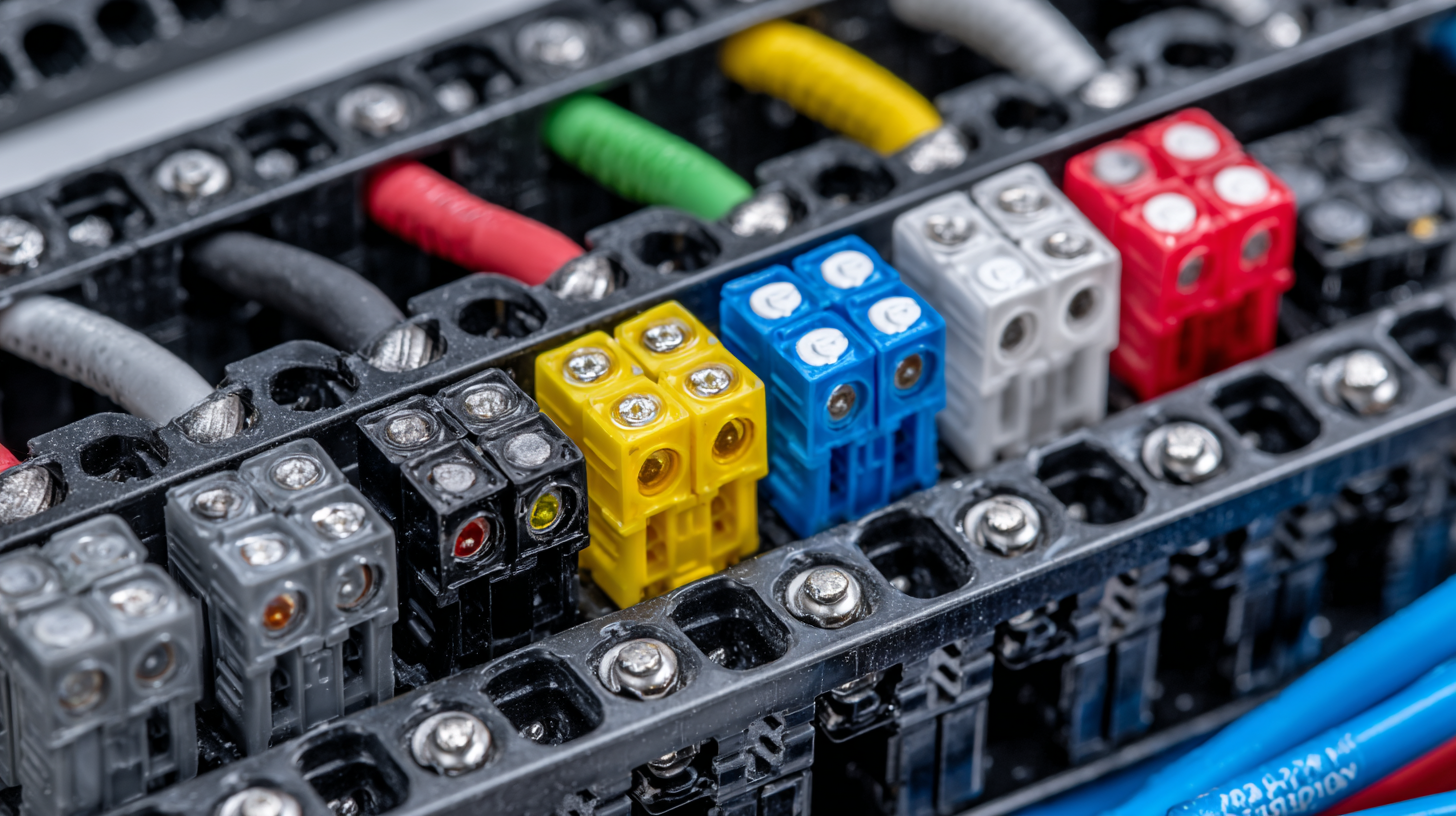

Understanding the Importance of Waterproof Wire Connectors in Projects

Waterproof wire connectors play a crucial role in ensuring the reliability and longevity of electrical connections, particularly in outdoor and industrial environments. According to the National Electrical Manufacturers Association (NEMA), more than 30% of electrical failures in outdoor settings are due to moisture infiltration, highlighting the need for effective waterproofing solutions. These connectors provide robust protection against rain, snow, and other environmental factors that can lead to electrical failures, making them indispensable for any project exposed to harsh conditions.

Moreover, industry data shows that electrical systems using waterproof connectors can reduce maintenance costs by up to 25%. This cost-effectiveness is particularly beneficial for industries such as automotive and construction, where equipment is frequently exposed to water and dust. Additionally, the use of waterproof connectors can enhance safety by preventing short circuits that might lead to equipment damage or fire hazards. Selecting the right waterproof wire connectors is not just a matter of convenience; it's a crucial investment in the reliability and safety of your projects.

Key Features to Look for in Quality Waterproof Wire Connectors

When selecting waterproof wire connectors for your projects, it's essential to focus on several key features that ensure reliability and durability. First and foremost, consider the level of waterproofing provided by the connectors. Look for connectors with an IP67 or higher rating, which signifies they can withstand immersion in water without allowing moisture to penetrate. This is critical for applications exposed to harsh weather conditions or underwater installations.

Another important feature is the material of the connector itself. High-quality connectors are typically made from corrosion-resistant materials such as nylon or thermoplastic elastomer (TPE). These materials not only enhance the longevity of the connector but also maintain their performance under varying temperature conditions. Additionally, pay attention to the sealing mechanism; connectors with robust sealing grommets or O-rings tend to provide superior protection against dust and moisture ingress. Always assess these features to ensure that your waterproof wire connectors can meet the demands of your specific project needs.

How to Choose the Best Waterproof Wire Connectors for Your Projects - Key Features to Look for in Quality Waterproof Wire Connectors

| Feature | Description | Importance Level |

|---|---|---|

| Material | Look for connectors made from high-quality materials like nylon or polycarbonate that resist UV exposure and aging. | High |

| Sealant Type | Connectors should have a reliable sealant, such as silicone or epoxy, to prevent water ingress. | High |

| Current Rating | Ensure connectors can handle the maximum current your project requires. | Medium |

| Temperature Range | Select connectors that perform well in extreme temperatures, suited for your environment. | Medium |

| Size & Compatibility | Connectors should match the wire gauge and dimension requirements of your project. | High |

| Ease of Use | Look for designs that facilitate quick and reliable installation without special tools. | Medium |

| IP Rating | Check the Ingress Protection (IP) rating for assurance against dust and water exposure. | High |

Types of Waterproof Wire Connectors and Their Applications

When selecting waterproof wire connectors for your projects, it’s essential to understand the various types available and their specific applications. One common type is the heat shrink connector, which is designed to create a watertight seal when heated. These connectors are perfect for automotive and marine applications, where moisture exposure is a significant concern. Additionally, these connectors often have built-in adhesive that further enhances their sealing capabilities.

Another popular option is the inline connector, typically used in outdoor lighting and garden projects. They feature a simple yet effective locking mechanism to ensure a secure connection that prevents water ingress. Inline connectors can also be daisy-chained, making them ideal for extending connections without compromising integrity across multiple fixtures.

**Tip 1:** Consider the environment in which the connectors will be used. For instance, if the connectors are subject to extreme temperatures or chemicals, choose connectors specifically designed to withstand those conditions.

**Tip 2:** Always check the IP (Ingress Protection) rating of the connectors, as this will help you determine their resistance to dust and moisture. A higher rating indicates better protection, ensuring a more reliable performance in demanding projects.

Tips for Proper Installation of Waterproof Wire Connectors

When it comes to ensuring the longevity and reliability of outdoor electrical projects, proper installation of waterproof wire connectors is crucial. According to the National Electrical Manufacturers Association (NEMA), improper connections account for over 25% of electrical failures in outdoor installations. To avoid these issues, thorough understanding and attention to detail during installation can make all the difference.

Tip 1: Always select connectors with an IP (Ingress Protection) rating suitable for your specific environment. For example, IP67 connectors are designed to withstand immersion in water up to 1 meter, while IP68 is suitable for prolonged underwater use. Choosing the right rating will protect your connections from moisture and dirt, eliminating potential corrosion.

Tip 2: Ensure all wires are stripped uniformly and that the wires fit snugly within the connectors. A study by the International Electrotechnical Commission (IEC) indicates that loose connections significantly increase electrical resistance, leading to overheating and potential failure. Using heat-shrink tubing in conjunction with your connectors can provide an extra layer of waterproofing, ensuring tighter seals and greater protection against environmental elements.

Common Mistakes to Avoid When Choosing Waterproof Wire Connectors

When selecting waterproof wire connectors for your projects, avoiding common pitfalls is crucial to ensure reliability and longevity. One frequent mistake is disregarding the environmental conditions where the connectors will be installed. For example, connectors exposed to extreme temperatures, moisture, or chemicals require specific ratings to withstand these challenges. Always check the specifications and choose connectors that are designed for the particular environment of your project.

Another common error is underestimating the importance of proper sizing and compatibility with the wire gauge. Using connectors that do not fit well can lead to poor conductivity and increased risk of failure. It's essential to ensure that the connectors match the wire size and type being used. Additionally, opting for the cheapest available connectors might save money initially but can lead to greater expenses down the line due to failures or replacements. Investing in quality connectors designed for durability can ultimately save you time and resources.

Related Posts

-

5 Reasons Why Wire EDM is the Best Choice for Precision Manufacturing in 2023

-

7 Benefits of Using Flat Plug Extension Cords for Home and Office Efficiency

-

How to Choose the Right Outdoor Extension Cord for Your Seasonal Needs and Safety Compliance

-

5 Essential Tips for Choosing the Right Electronic Wire for Optimal Performance

-

10 Compelling Reasons Why Cable Wire is Essential for Your Global Sourcing Needs

-

Top Quality Electrical Wire Connectors From a Leading Chinese Manufacturer for Global Export