How to Choose the Best Waterproof Wire Connectors for Your Project

In today's increasingly interconnected world, the importance of reliable electrical connections cannot be understated, especially in environments exposed to moisture and harsh weather conditions. According to a report by MarketsandMarkets, the global market for waterproof wire connectors is projected to reach $1.5 billion by 2025, driven by rising demand across various sectors including automotive, telecommunications, and renewable energy. Choosing the right waterproof wire connectors for your project is crucial not just for maintaining performance, but also for ensuring safety and longevity. With a plethora of options available, understanding their specifications, applications, and industry standards is essential for making informed decisions that best suit your project's needs. Whether you're tackling a DIY project or overseeing large-scale installations, having the right waterproof wire connectors can significantly impact the reliability and durability of your electrical systems.

Understanding Different Types of Waterproof Wire Connectors: A Comparative Analysis

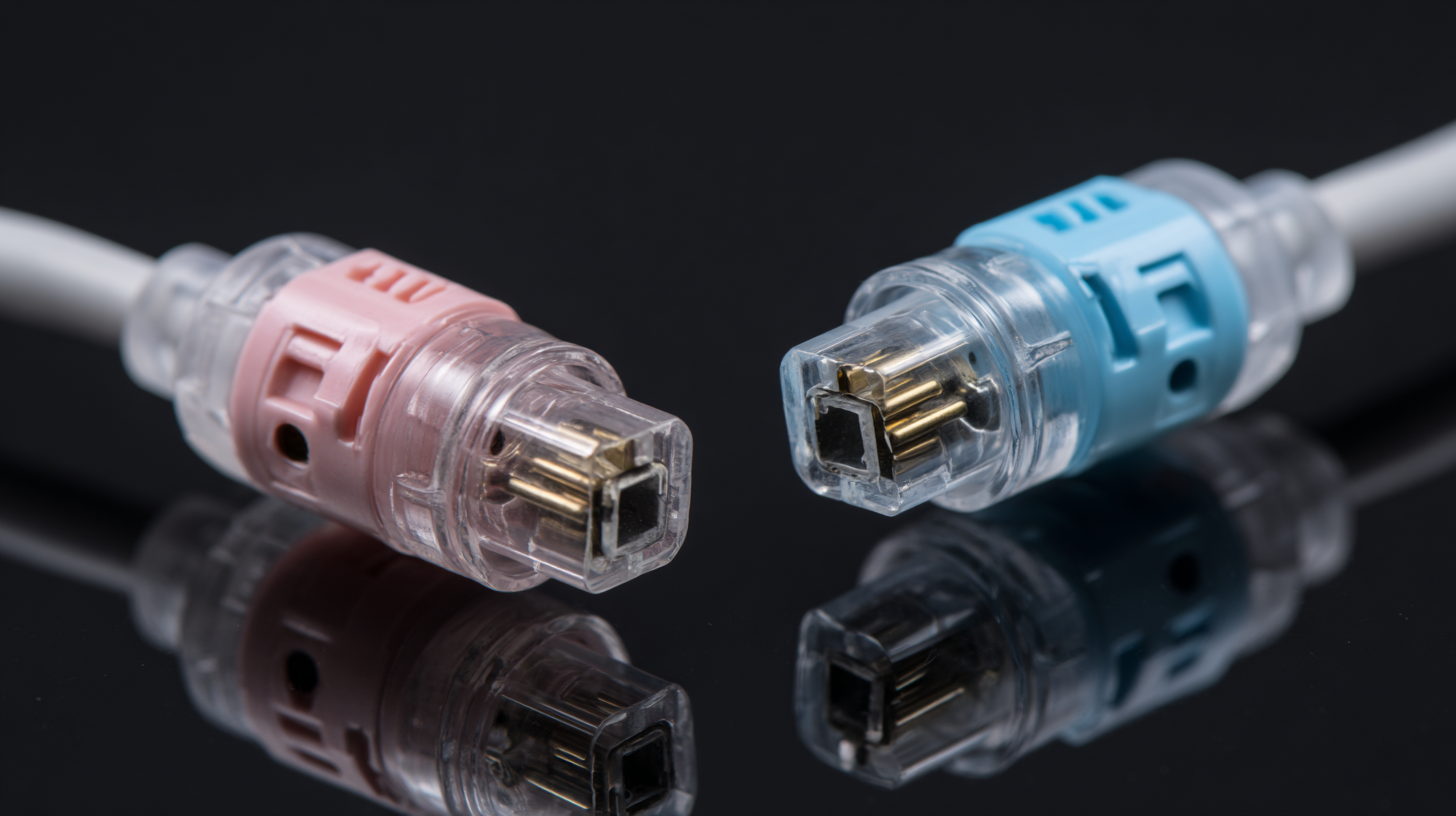

When selecting waterproof wire connectors for your project, understanding the various types available is crucial. There are three primary types of waterproof connectors: heat shrink, gel-filled, and threaded connectors. Heat shrink connectors utilize a heat-activated adhesive that forms a watertight seal when heated. These are ideal for applications requiring flexibility and a strong bond, making them suitable for automotive and marine use.

In contrast, gel-filled connectors incorporate a silicone gel that protects against moisture and oxidation. These connectors are particularly advantageous for outdoor installations, as the gel provides an effective barrier against water and environmental elements. Lastly, threaded waterproof connectors create a secure mechanical seal that prevents water ingress, making them perfect for industrial settings where heavy-duty reliability is essential. By understanding these distinctions, you can make an informed choice to ensure the longevity and safety of your electrical connections.

Evaluating Waterproof Ratings: IP67 vs. IP68 and Their Applications in Electrical Projects

When selecting waterproof wire connectors for your electrical projects, understanding the significance of waterproof ratings like IP67 and IP68 is crucial. The Ingress Protection (IP) ratings indicate the degree of protection provided against dust and water infiltration. An IP67 rating means that the connector can withstand immersion in water up to 1 meter for 30 minutes, while an IP68 rating surpasses this by being designed for continuous immersion beyond 1 meter, usually specified by the manufacturer. This distinction is essential for projects exposed to varying environmental conditions, ensuring longevity and performance.

In today’s market, waterproof technology is becoming increasingly relevant. For instance, recent innovations in mobile devices highlight how IP ratings influence consumer choices. Devices featuring an IP68 rating are gaining popularity as they promise robust durability and reliability during outdoor use. It's imperative to assess your project's specific needs when choosing connectors, as opting for an IP68-rated component offers enhanced protection for applications in harsh environments, potentially saving costs related to repairs and replacements.

**Tips:**

- Always verify the manufacturer's certification to ensure the stated IP rating is reliable before making a purchase.

- Consider the environment where the connectors will be used; if it’s likely to be submerged or exposed to heavy rain, opting for the higher IP68 rating is advisable for optimal protection.

How to Choose the Best Waterproof Wire Connectors for Your Project

| Connector Type | IP Rating | Waterproof Level | Typical Application |

|---|---|---|---|

| Standard Waterproof Connector | IP67 | Protected against immersion in water up to 1 meter for 30 minutes | Outdoor lighting, garden irrigation |

| Premium Waterproof Connector | IP68 | Protected against continuous immersion in water, typically above 1 meter | Underwater applications, marine electronics |

| Submersible Connector | IP68 | Suitable for prolonged submersion | Water pumps, underwater cameras |

| Industrial Connector | IP67 | Water resistant against splashing and immersion | Manufacturing equipment, outdoor sensors |

| Automotive Connector | IP67 | Challenged by heavy rain and splashes | Vehicle lighting, engine components |

Material Matters: Selecting the Right Plastics and Metals for Durability and Corrosion Resistance

When selecting waterproof wire connectors, the choice of materials plays a crucial role in ensuring the durability and effectiveness of the connections in various environments. Plastics and metals serve as the primary components that determine how well these connectors withstand exposure to moisture, chemicals, and extreme temperatures. For plastics, options such as polycarbonate and nylon are often preferred for their high impact resistance and low moisture absorption. These materials help prevent degradation and ensure a long-lasting seal.

On the other hand, metals used in connectors must exhibit excellent corrosion resistance, especially in marine or industrial applications. Stainless steel and marine-grade brass are popular choices due to their ability to endure harsh conditions without succumbing to rust or wear. Additionally, protective coatings can further enhance metal connectors' resistance to corrosive elements. Ultimately, selecting the right combination of plastics and metals not only increases the longevity of your waterproof connectors but also maintains the integrity of electrical connections in challenging environments.

Key Features to Look For: Wire Gauge Compatibility and Temperature Ratings for Optimal Performance

When selecting waterproof wire connectors, understanding wire gauge compatibility is crucial for optimal performance in your project. The wire gauge refers to the thickness of the wire, which directly affects its current-carrying capacity and resistance. A connector that is mismatched with the wire gauge can lead to overheating, reduced efficiency, or even failure. Therefore, ensure that the connectors you choose are designed to accommodate the specific wire sizes in your application. This consideration not only promotes safety but also enhances the reliability of the connections in harsh environments.

Another important feature to consider is the temperature rating of the connectors. Different projects may require functionality under varying temperature conditions, such as extreme cold or heat. Selecting connectors with suitable temperature ratings ensures that they will maintain their integrity and performance, preventing issues like corrosion or brittleness over time. Whether you need connectors for automotive, marine, or outdoor applications, paying attention to both wire gauge compatibility and temperature ratings will significantly improve the longevity and effectiveness of your electrical connections.

Cost vs. Quality: Finding the Best Value in Waterproof Connectors for DIY and Professional Use

When selecting waterproof wire connectors for any project, the balance between cost and quality becomes crucial, especially for DIY enthusiasts and professionals alike. According to a recent report by the Electrical Wiring Association, investing an extra 20% in higher-quality connectors can significantly enhance longevity and reliability, reducing failure rates by approximately 30% in outdoor installations. This statistic emphasizes the importance of not only looking for the most affordable options but also considering the long-term value of the product.

Moreover, the type of environment plays a vital role in choosing the right connectors. For instance, connectors designed for marine applications are specifically tested to withstand harsh conditions, including saltwater corrosion and extreme temperatures. A study published in the Journal of Electrical Engineering found that connectors with high-quality seals and materials, such as nylon or polyethylene, outperform budget alternatives by as much as 50% in durability. Thus, while it might be tempting to go for lower-priced options, opting for connectors that provide better protection and performance adds significant value to both DIY and professional projects.

Related Posts

-

How to Choose the Best Waterproof Wire Connectors for Your Projects

-

How to Maximize Your Gains with a Smith Machine with Cables for Effective Resistance Training

-

5 Reasons Why Wire EDM is the Best Choice for Precision Manufacturing in 2023

-

5 Essential Tips for Choosing the Right Electronic Wire for Optimal Performance

-

What is the Importance of Using Outdoor Extension Cords for Your Projects

-

Exploring Innovative Alternatives to the Smith Machine with Cables for Enhanced Workouts