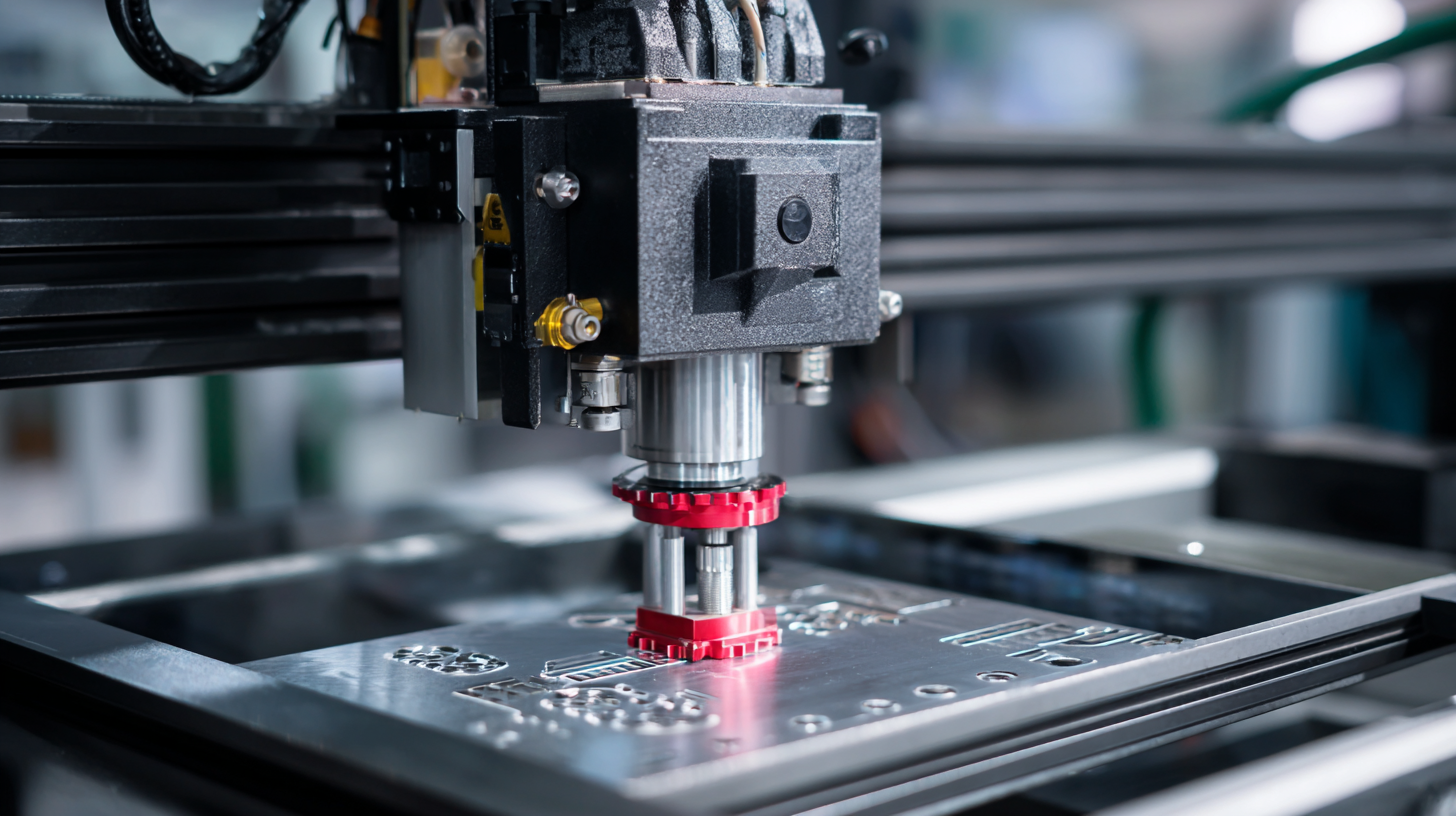

Unlocking the Advantages of Wire Feed Welders: Efficiency, Precision, and Cost-Effectiveness in Modern Fabrication

In the realm of modern fabrication, the wire feed welder has emerged as a transformative tool, revolutionizing the way metalworking projects are approached. By combining efficiency, precision, and cost-effectiveness, wire feed welders offer significant advantages for both novice and experienced welders alike. This guide aims to unlock the potential of wire feed welding technology, exploring its capabilities and the numerous benefits it presents in various applications. From automotive repairs to industrial manufacturing, understanding how to effectively utilize a wire feed welder can enhance productivity and deliver high-quality results. Whether you are just starting your welding journey or looking to refine your skills, this comprehensive overview will provide the insights needed to harness the full power of wire feed welding in your fabrication projects.

Understanding Wire Feed Welders: Key Features and Benefits

Wire feed welders are becoming increasingly popular in modern fabrication due to their unique features and benefits. One of the key advantages is their efficiency; according to the American Welding Society, wire feed welding processes can enhance productivity by up to 30% compared to traditional welding techniques. This is primarily due to the continuous feeding of wire, which reduces downtime for reloading and allows for longer welding periods without interruptions.

Precision is another pivotal feature of wire feed welders. These machines utilize advanced technology that ensures consistent arc stability and reduced heat input, which are critical for intricate jobs. A report by the Welding Research Council highlights that wire feed welding techniques result in a 25% reduction in distortion, making them suitable for work that demands high accuracy and minimal rework. Additionally, the versatility of wire feed welders allows for a variety of materials to be processed with precision, catering to diverse fabrication needs in industries ranging from automotive to construction.

Cost-effectiveness further solidifies the appeal of wire feed welders. With lower operational costs and reduced material wastage, businesses are seeing a significant return on investment. According to a study by the Fabricators and Manufacturers Association, companies utilizing wire feed welding techniques can achieve savings of up to 15% on material costs, thanks to the efficient use of filler materials and reduced rework times. These combined benefits position wire feed welders as a valuable asset in any modern fabrication operation.

Maximizing Efficiency: Best Practices for Using Wire Feed Welders

Wire feed welders have transformed modern fabrication by enhancing efficiency and precision in welding processes. According to a report from the American Welding Society, using wire feed technology can improve welding speed by up to 30% compared to traditional methods. This increase is primarily due to the continuous feeding of the welding wire, which minimizes the need for stopping and starting, thereby allowing for a more streamlined workflow.

To maximize the efficiency of wire feed welders, implementing best practices is essential. Ensuring proper setup and maintenance of equipment is critical; for instance, regular inspection of the drive rolls and liner can prevent feed issues that lead to downtime. Furthermore, selecting the right wire and shielding gas according to the project specifications can significantly enhance the quality of the welds and reduce defects. A study by the Fabricators & Manufacturers Association revealed that companies adopting systematic maintenance strategies report a 25% reduction in operational costs over time, highlighting the importance of efficiency in cost-effectiveness.

Achieving Precision: Techniques for Accurate Wire Feed Welding

Wire feed welding has transformed modern fabrication, offering unmatched precision and efficiency. Achieving accuracy in wire feed welding relies heavily on mastering specific techniques. One crucial technique is maintaining the correct wire feed speed. Too fast a feed rate can lead to poor arc stability, while too slow can result in insufficient penetration. It’s essential to find the optimal speed for the material and thickness being welded.

Another vital aspect of precision is the angle of the welding torch. Holding the torch at the correct angle not only enhances penetration but also ensures a cleaner bead. For most applications, a 10 to 15-degree angle from vertical is recommended, as this promotes better shielding gas coverage and minimizes contamination.

**Tips:** Always perform a test weld on a scrap piece before starting the actual project to fine-tune your settings. Additionally, regularly maintaining your welding equipment—such as checking the liner for wear and ensuring the correct tension on the wire feed roller—can prevent inconsistencies during the welding process. Implementing these techniques fosters better results in wire feed welding, significantly improving the quality of your fabricated components.

Cost-Effectiveness: Evaluating the Economic Advantages of Wire Feed Welders

Wire feed welders have emerged as a compelling choice in modern fabrication, primarily due to their cost-effectiveness and operational efficiency. Industry reports indicate that utilizing wire feed technology can reduce material waste by up to 30% compared to traditional welding methods. This significant reduction not only diminishes overall costs but also aligns with the growing focus on sustainability in manufacturing processes. The precision of wire feed welders further enhances their economic advantages as they can deliver consistent results with minimal rework, thereby optimizing labor and resource allocation.

Moreover, recent advancements in cold metal transfer (CMT) technology have introduced remarkable efficiencies in welding operations. This innovative approach allows for lower heat input, which minimizes distortion and improves the mechanical properties of welds. According to studies, CMT can increase deposition rates by as much as 50%, presenting a strong case for its adoption across various fabrication sectors. As industries continue to navigate the challenges of rising production costs, the economic benefits of wire feed welders, coupled with emerging technologies like CMT, position them as a crucial asset for achieving both financial and operational goals.

Unlocking the Advantages of Wire Feed Welders: Efficiency, Precision, and Cost-Effectiveness in Modern Fabrication

| Dimension | Wire Feed Welding | Traditional Welding |

|---|---|---|

| Efficiency (Weld Speed) | Up to 50% faster | Standard speed |

| Precision | High - minimal spatter | Moderate |

| Cost of Equipment | Moderate | Lower |

| Operating Cost (per hour) | $10 - $15 | $20 - $30 |

| Skill Level Required | Intermediate | Advanced |

| Material Waste | Low | High |

Maintaining Your Wire Feed Welder: Tips for Optimal Performance and Longevity

Maintaining your wire feed welder is crucial for ensuring optimal performance and longevity. Regular maintenance checks can significantly enhance its efficiency and extend its lifecycle. One of the fundamental tips is to keep the welding machine clean. Accumulation of debris and spatter can clog the wire feed tubes and contact tips, leading to inconsistent feeding and poor weld quality. A routine cleaning schedule will prevent these issues and contribute to smoother operation.

Another essential aspect of maintenance is checking the wire feed speed and tension regularly. If the speed is set too high or too low, it can cause feed problems or result in poor welds. Adjusting the tension properly will allow for better control over the wire, leading to precision in your welding tasks. Additionally, inspect the welding wire for any signs of rust or damage before use, as a good quality wire is key to achieving reliable welds.

Finally, ensure that the cooling system of your wire feed welder is functioning properly. Overheating can cause extensive damage to internal components. Make it a habit to monitor the temperature during operation and allow your welder to cool down after prolonged use. By following these maintenance tips, you can unlock the full potential of your wire feed welder and maintain its performance over the years.

Related Posts

-

Ultimate Guide to Choosing the Right Cabling Machine for Your Production Needs

-

5 Essential Tips for Choosing the Right Electronic Wire for Optimal Performance

-

The Comprehensive Ultimate Guide to Understanding Electrical Cable Selection and Installation

-

Challenges in Utilizing Flat Plug Extension Cords: Insights from Industry Data and Trends

-

5 Reasons Why Wire EDM is the Best Choice for Precision Manufacturing in 2023

-

How to Choose the Right Outdoor Extension Cord for Your Seasonal Needs and Safety Compliance