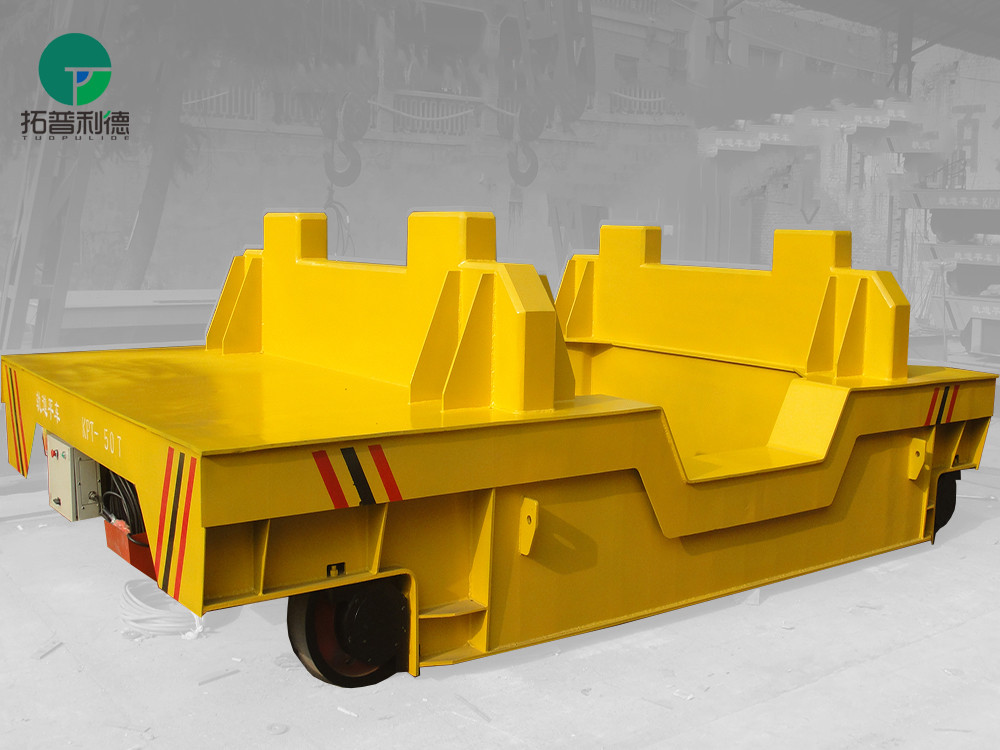

Explosion-Proof AC Powered Foundry Steel Ladle Transfer Vehicle Transport Carts for Ladle

Brief Introduction - Transport Carts For Ladle

The Explosion-Proof AC Powered Foundry Steel Ladle Transfer Vehicle Transport Carts for Ladle is an electric operated material transfer cart which is powered by conductor rail and running on the rails. This motorized transport cart is designed to transfer hot ladle with an external temperature up to 350° C: it has a suitable protection for engines and it is painted with an heat resistant paint

As the steel ladle transfer vehicles are equipped with steel wheels and move on steel rails they are suited to very high loading capacities thanks to the very low friction between steel and steel. The capacity load can up to 500 tons.

Working Principle - Transport Carts For Ladle

The kinds of rail operated ladle transfer vehicle, which is powered by conductor rails. It makes the AC electricity power is transformed into AC 36v two-phase and are respectively connected to the two rails. Then the transport cart for ladle conduct the AC 36v on rail into the electrical appliance box at the bottom of the cart. And then the AC 36v is transformed into DC 36v to control the DC motor. Use this principle to make the transport cart start, stop, go forward and backward, adjust the speed and so on.

Product Features - Transport Carts For Ladle

1. High quality reducer, gears adopt CNC grinding technology, high precision, good contact, high transmission efficiency, high bearing capacity and long service life.

2. High quality motor, with a correspondingly fast, large starting torque, from zero speed to rated speed with rated torque performance.

3. The wheel adopts angular bearing seat for easy installation and adjustment, in order to properly improve the machining accuracy of the relevant parts to improve the accuracy of the transport cart's installation and manufacturing, to place the wheel deviation, the contact between the rim and the track intensifies the rim wear and increases the frictional resistance and so on.

4. High degree of automation, to achieve unmanned automated production processes.

Parameter List - Transport Carts For Ladle

|

Model

|

KPD-5T

|

KPD-20T

|

KPD-30T

|

KPD-40T

|

KPD-50T

|

KPD-63T

|

|

Rated load (T)

|

5

|

20

|

30

|

40

|

50

|

63

|

|

Table size

|

length(L)

|

3500

|

4000

|

4500

|

5000

|

5500

|

5600

|

|

Width(W)

|

2000

|

2200

|

2200

|

2500

|

2500

|

2500

|

|

Height(H)

|

450

|

550

|

600

|

650

|

650

|

750

|

|

Wheel Base (mm)

|

2500

|

2800

|

3200

|

3800

|

4200

|

4300

|

|

Rail Inner Gauge (mm)

|

1435

|

1435

|

1435

|

1435

|

1435

|

1435

|

|

Wheel Diameter(mm)

|

Φ300

|

Φ350

|

Φ400

|

Φ500

|

Φ500

|

Φ600

|

|

Wheel Quantity(Nos)

|

4

|

4

|

4

|

4

|

4

|

4

|

|

Ground Clearance (mm)

|

50

|

50

|

50

|

50

|

50

|

75

|

|

Running speed (m/min)

|

0-25

|

0-20

|

0-20

|

0-20

|

0-20

|

0-20

|

|

Motor Power (Kw)

|

1.2

|

2.2

|

3.5

|

4

|

5

|

6.3

|

|

Transformer Power (KVA)

|

5

|

6.8

|

10

|

10

|

10

|

20

|

|

Transformer Quantity (Pcs)

|

1

|

1

|

1

|

1

|

1

|

1

|

|

Running Distance (m)

|

80

|

80

|

80

|

60

|

50

|

50

|

|

Max Wheel Load (KN)

|

25.8

|

77.7

|

110.4

|

142.8

|

174

|

221.4

|

|

Reference Weight (T)

|

3.6

|

5.9

|

6.8

|

7.6

|

8

|

10.8

|

|

Recommended Rail Model

|

P18

|

P24

|

P38

|

P43

|

P43

|

P50

|

Applications - Transport Carts For Ladle

Our transport cart not only can transport all kinds of lalde in steel mill, it is also can be widely applied in Metallurgy, Machinery Fabrication, Auto makers, Heavy Industrial, Light Industrial, Mold Maker, Construction Machinery maker, Shipyard, Port Cargo Yard, Steel Transfer, Mining Transfer, Air and Space as well as Military industries and so on to transfer and handling equipment or material from workshop to workshop or from bay to warehouse.

Production Process - Transport Carts For Ladle

CNC Cutting

Transport the steel plate from raw material warehouse to CNC cutting workshop for cutting. After the cutting, the workers will do some simple processing such as chip moving and setting out.

Preliminary Assembling

Put the cut steel plate together according to the design drawing

Welding

Weld the steel plate with automatic welding machine after the preliminary assembling

Post weld treatment

Test the welding section after the welding, polish and burring. Post weld treatment to eliminate welding stress

Spray Primer

Transport the structure part after processing to painting booth for spraying primer. The main component of the primer is zinc rich epoxy antirust paint. The primer is to two layers

Assembling

Assemble the structure parts after spraying primer with wheels, motors and gear box, etc.

Paint finish

Transport the assembled cart to painting booth, inspect the integrity of primer. After that paint the finish

Debugging

Debugging the vehicle after painting the finish with electric control system, after the debugging, the vehicle will test without load. And after the no load test, the cart will be tested with load. After the inspection, the cart will be transported to storage area.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!